Jump Machinery (Shanghai) Limited

Milk Yogurt Processing Plant,Yogurt Butter Processing Plant,Milk Cheese Processing Plant Machinery

Jump Machinery (Shanghai) Limited

Milk Yogurt Processing Plant,Yogurt Butter Processing Plant,Milk Cheese Processing Plant Machinery

| Payment Type: | L/C,T/T |

|---|---|

| Incoterm: | FOB,CFR,CIF,EXW |

| Min. Order: | 1 Set/Sets |

Condition: New

Model Number: JUMP-FQJL

Type: milk processing plant

Power: 3kw

Dimension(L*W*H): 2100*1460*1590mm

Warranty: 1 Year

After-sales Service Provided: Engineers Available To Service Machinery Overseas

Product Name: Complete yogurt milk cheese processing plant for sale

Material: 304 Stainless Steel

Application: Kinds

Function: Multifunctional

Usage: Industrial Usage

Capacity: 500kg/h-150T/h

Item: Industrial plant machine

Color: Customers' Requirements

Name: yogurt processing plant

Feature: Turn Key Project

Place Of Origin: Shanghai, China

Voltage: 220V/380V

Weight: 50 TONS

Certification: ISO 9001,CE

Packaging: 1.Stable wooden package protects machine from strike and damage. 2.Wound plastic film keeps machine out of damp and corrosion. 3.Fumigation-free package helps the smooth customs clearance. 4.The big size machine will be fixed in container without package

Transportation: Ocean

Supply Ability: 3 Set/Sets per Month yogurt processing plant

Port: Shanghai

Payment Type: L/C,T/T

Incoterm: FOB,CFR,CIF,EXW

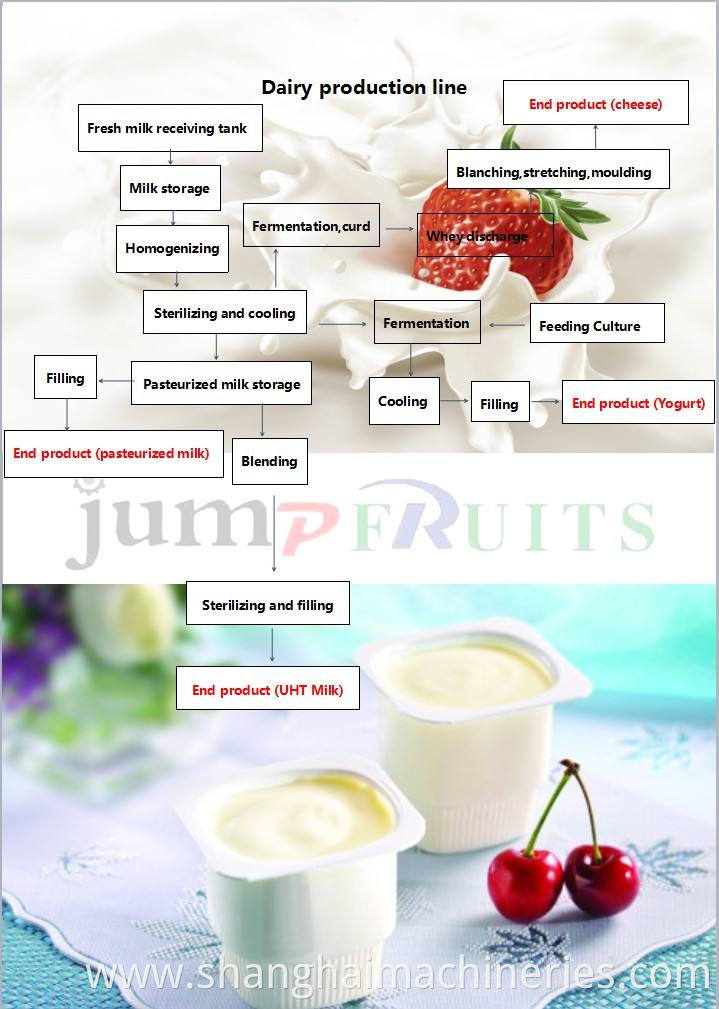

This machine can fully automate the production and packaging of yogurt and other dairy products. As a manufacturer, we can customize all kinds of food machinery and production lines according to the needs of customers. For Turnkey Food Beverage Production Line/Can Food Machinery/ Fruits Juice Machinery/Tomato Sauce Machinery/Fruits Jam Machinery/Milk Yogurt Machinery Please Contact us. The whole Yoghurt Processing Line includes the following parts: Water Treatment section; Milk Receiving Section; Sugar Melting System; Sterilization Section; Fermenting Section; Filling Packing Section; According the customer require: CIP Cleaning Section, Chiller Section, Compressor, Cooling Room.

This milk production line mainly includes the following machines:

1. Milk weighing tank

2. Milk collection tank

3. Direct-cooling milk storage tank

4. High-speed mixing tank

5. High-speed homogenizer

6. UHT instant Sterilizer

7. Aseptic tank

8. Plate heat exchanger

9. Side sealing machine

10. CIP cleaning device

11. Return pump

12. Steam boiler

Name: Spray drying

Brand: Jump

Original: China

This equipment is used to dry solid liquid such as solution and suspending liquid. In the tower, the materials can be heated in short time and evaporated quickly and the temperature of heat exchanger is lower so that it has little impact on the solubility, color, flavor and nutrition of the

product. Therefore, this equipment is widely used in the industries of food, medicine and

chemical products, especially suitable to dry the heat-sensitive materials by spraying such as

thick milk, soy milk, egg liquid, blood meal, medicament, yeast and food additives.

Name: Bliwing Cylinder

Brand: FESTO

Original: Germany

Special suitable for fruit/vegetable paste and juice or juice concentrate,dairy product and other high viscous or fluent product.

Applicable to aluminum foil compound aseptic bag from 5L-220L or 1000L by means of easy adjustment with simple change parts.Easily adjustable with simple change parts according to

The unite is consisted of: aseptic filling head, accurate electronic balance, drum conveying roller, PLC Control system, control cabinet, steam barrier and protection system, operation platform, etc.Main structure with SUS304 stainless steel, combined Italy technology and based on

Europe standard.

Provide several security measures(position controlling, computation controlling, temperature controlling) to prevent the machine from destroying and guarantee the product’s quality Products’ valves, filler head and other moving parts have steam barrier for protection

Keep the filling chamber sterilized all the time using steam protection

When shifting the aseptic bag or some thing wrong with the filler, the product will be auto backtracked into the buffer tank before the tube in tube sterilizer.

Full aUto CIP(clean in place) and SIP(sterilize in place) available simultaneously together with tube in tube sterilizer

Automatically print the black and white label and other data the customer specified such as the filling date, filling time, filling weight, product code or others, if you required.

Product Categories : Milk Yogurt Machinery > Dairy Production Line