Jump Machinery (Shanghai) Limited

Industrial Automatic Chilli Paste Making Machines,Industrial Automatic Chilli Paste Making Equipment,Industrial Automatic Chilli Paste Making Machinery

Jump Machinery (Shanghai) Limited

Industrial Automatic Chilli Paste Making Machines,Industrial Automatic Chilli Paste Making Equipment,Industrial Automatic Chilli Paste Making Machinery

| Unit Price: | USD 160000 / Set/Sets |

|---|---|

| Payment Type: | L/C,T/T |

| Min. Order: | 1 Set/Sets |

After-sales Service Provided: Engineers Available To Service Machinery Overseas

Feature: High Efficiency

Warranty: 1 Year

Condition: New

Brand Name: Oem

Video Outgoing-inspection: Provided

Machinery Test Report: Provided

After Warranty Service: Video Technical Support, Online Support, Spare Parts, Field Maintenance And Repair Service

Warranty Of Core Components: 1 Year

Voltage: 220v/380v

Material: 304 Stainless Steel

Function: Multifunctional

Core Components: Motor

Local Service Location: Uzbekistan

Place Of Origin: Shanghai, China

Power: 3kw

Usage: Food Processing Industries

Weight: 60 Kg

Dimension(L*W*H): 1380*1200*2000mm

Applicable Industries: Machinery Repair Shops, Manufacturing Plant, Food & Beverage Factory, Farms, Food Shop, Food & Beverage Shops

Application: Root Vegetables

Type: processing line

Name: Vegetable Cutting Machine

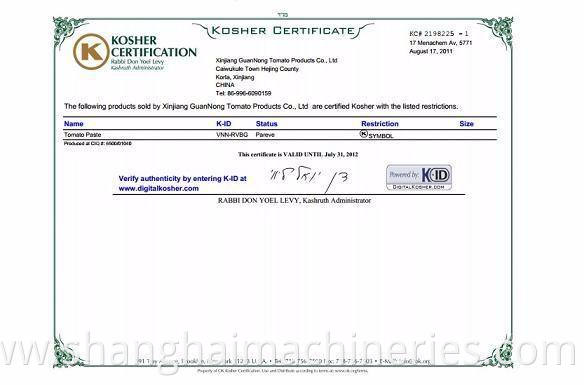

Certification: ISO 9001,CE

Capacity: 3-5t/h

Product Name: Shanghai Fruit Jam processing plant

Item: Automatic Fruits jam Making Machine

Packaging: carton box

Transportation: Ocean,Land,Air

Supply Ability: 30 Set/Sets per Month

Port: Shanghai

Payment Type: L/C,T/T

C. Crusher

Fusing Italian technology, multiple sets of cross-blade structure, crusher size can be adjusted according to customer or specific project requirements, it will increase the juice juice rate of 2-3% relative to the traditional structure , which is suitable for production of onion sauce, carrot sauce, pepper sauce , apple sauce and other fruits and vegetables sauce and products

D. Double-stage pulping machine

It have tapered mesh structure and the gap with load can be adjusted, frequency control, so that the juice will be cleaner; Internal mesh aperture are based on customer or specific project requirements to order

E. Evaporator

Single-effect, double-effect,triple-effect and multi-effect evaporator, which will save more energy; Under vacuum, continuous low temperature cycle heating to maximize the protection of nutrients in the material as well as the originals. There are steam recovery system and double times condensate system, it can reduce the consumption of steam;

F. Sterilization machine

Having obtained nine patented technology, take full advantages of the material's own heat exchange to save energy-- about 40%

F. Filling machine

Adopt Italian technology, sub-head and double-headed, continuous filling, reduce return; Using steam injection to sterilize, to ensure filling in aseptic state , the shelf life of product will twp years at room temperature ; In the filling process,using turntable lifting mode to avoid secondary pollution.

Product Categories : Alcohol Production Line > Wine Production Line