Jump Machinery (Shanghai) Limited

Production Line Machine,Commercial Fruit Juicer Machine,Fresh Fruits Production Line

Jump Machinery (Shanghai) Limited

Production Line Machine,Commercial Fruit Juicer Machine,Fresh Fruits Production Line

| Payment Type: | L/C,D/P,D/A,T/T,MoneyGram,trade on alibaba |

|---|---|

| Incoterm: | FOB |

| Min. Order: | 1 Set/Sets |

Brand: JUMP

Applicable Industries: Manufacturing Plant, Food & Beverage Factory

Showroom Location: None

Video Outgoing-inspection: Provided

Machinery Test Report: Provided

Marketing Type: New Product 2020

Warranty Of Core Components: 1 Year

Core Components: Plc, Motor, Pump

Model Number: cts0905

Brand Name: sh-jump

Power: 4kw

Dimension(L*W*H): 1100*265*920mm

Warranty: 12 Months

Application Fields: Fruit processing plant

Key Selling Points: High Productivity

After-sales Service Provided: Engineers available to service machinery overseas

Condition: New

Production Capacity: 0.5-500T/H

Capacity: 1-5t/h

Material: SUS304

Raw Material: Fresh fruits

Advantage: long-long after-sales Service

Application: Fruit processing line

Color: Customers' Requirements

Type: turn key processing line

After Warranty Service: Video technical support, Online support, Spare parts, Field maintenance and repair service

Local Service Location: None

Applicable Industry: Manufacturing Plant, Food &Amp; Beverage Factory

Out-of-warranty Service: Video Technical Support, Online Support

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): Egypt, Germany, Pakistan, Australia, Kazakhstan, Colombia, Algeria, Ukraine, Morocco, India, Viet Nam, Canada, Turkey, Philippines, Mexico

Showroom Location (in Which Countries Are There Sample Rooms Overseas): Algeria

Video Factory Inspection: Provided

Mechanical Test Report: Provided

Core Component Warranty Period: 1 Year

Place Of Origin: China

Warranty Period: 1 Year

Application Field: Fruit Processing Plant, Vegetable Processing Plant

Applicable Raw Materials: Fruit

Core Selling Point: Automatic

Place Of Origin: Shanghai, China

Voltage: 380V

Weight: 100 KG

Certification: CE ISO

Packaging: standard export package, wrapped by plastic film and in wooden case

Productivity: 500kg-5t/h

Transportation: Ocean

Place of Origin: Shanghai

Supply Ability: 8 Set/Sets per Month fruit juicer production line machine

Certificate: ISO/CE

Port: Shanghai

Payment Type: L/C,D/P,D/A,T/T,MoneyGram,trade on alibaba

Incoterm: FOB

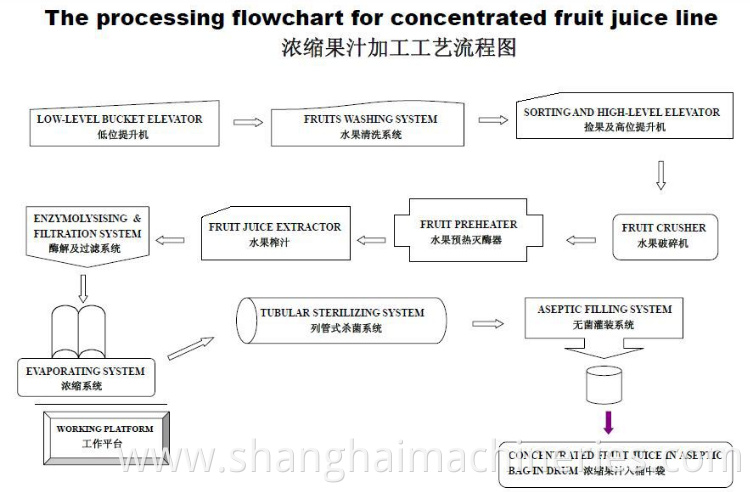

A:Can Food Machinery promotion system of the original fruits, cleaning system, sorting system, crushing system, pre-heating sterilization system, pulping system, vacuum concentration system, sterilization system, aseptic filling system

B: Fruits Juice Machinery pump → blending drum → homogenization →deaerating → sterilization machine → washing machine → filling machine → capping machine → tunnel spray Sterilizer → dryer → coding → boxing

Main characteristic:

1 Used to wash fresh tomato, strawberry, mango, etc.

2 Special design of surfing and bubbling to ensure a through cleaning and lessening the damage to the fruit as well.

3 Suitable for many kinds of fruit or vegetables, such as tomato, strawberry, apple,mango,etc.

Motor Power: 3KW

Applied to the refinement or emulsification of juice, jam, beverage.

With frequency conversion control and centralized control cabinet

Rated handling capacity 1T/H

Semi-automatic cleaning system

Including acid tank ,base tank ,hot water tank, heat exchange system and controlsystems. Cleaning all the line.

Power:7.5KW

Main characteristic:

1. Stainless steel construction on all contact surfaces, a totally enclosed stainless steel construction on all contact surfaces, a totally enclosed stainless steel piping system to transport the juice to stainless steel finishers.

2. Citrus extraction system is unique in that is simultaneously recovers oil as well as juice during the same extraction cycle.

3. Bitter constituents such as cores, membranes, seeds, etc., are instantaneously separated from the juice and juice cells by the pre-finisher tube during the extraction cycle.

4. This outstanding performance is made possible due to the ability of the Citrus Extractor to squeeze citrus fruit efficiently at wide range of size and shape.

5. Handle most of the world’s citrus varieties and sizes. This minimizes the number of extractors required, resulting in space savings and reduced equipment costs.

6. Water usage and waste disposal are minimized through the use of water recycle systems.

Product Categories : Tomato Sauce Machinery > Tomato Sauce Processing Line