Jump Machinery (Shanghai) Limited

Pasta Processing Line,Pasta Crushing Machine,Pasta Production and Processing Equipment

Jump Machinery (Shanghai) Limited

Pasta Processing Line,Pasta Crushing Machine,Pasta Production and Processing Equipment

Brand: JUMP

Status: New

Applicable Industry: Manufacturing Plant, Food &Amp; Beverage Factory

Out-of-warranty Service: Video Technical Support, Online Support

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): Egypt, Canada, Germany, Viet Nam, Australia, Pakistan, Colombia, Kazakhstan, Morocco, Ukraine, Algeria, India, Mexico, Turkey, Sri Lanka, Kenya, Philippines, Nigeria, Kyrgyzstan, Romania, United Kingdom, Russia, Brazil, Argentina, South Korea, Peru, United States, Spain, Uzbekistan, Bangladesh, Tajikistan, Chile, South Africa, Saudi Arabia, Thailand, Italy, Japan, Malaysia, Indonesia, France, Uae

Showroom Location (in Which Countries Are There Sample Rooms Overseas): Algeria

Video Factory Inspection: Provided

Mechanical Test Report: Provided

Marketing Type: Ordinary Product

Core Component Warranty Period: 1 Year

Core Components: Plc

Place Of Origin: China

Warranty Period: 1 Year

Application Field: Snack Food Factory

Packaging: Wooden packing

Productivity: 500kg-5t/h

Transportation: Ocean

Place of Origin: Shanghai

Supply Ability: 1-100

Certificate: ISO/CE

Port: Shanghai

Payment Type: D/A

Incoterm: FOB

For Turnkey Food Beverage Production Line/Can Food Machinery/ Fruits Juice Machinery/Tomato Sauce Machinery/Fruits Jam Machinery/Milk Yogurt Machinery Please Contact Tony Wu:008116770215888

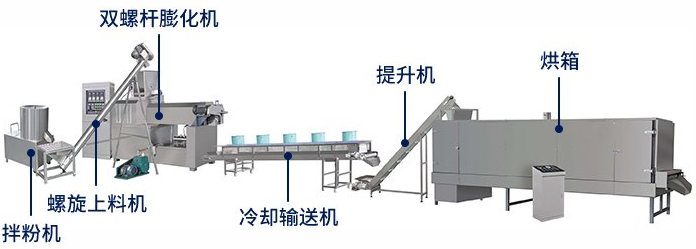

Macaroni production line equipment composition: mixing machine→screw elevator→single screw main machine→conveyor cutting machine→cooler→hot air dryer

Product Categories : Snack Food Production Line > Pasta Turnkey Production Line