Jump Machinery (Shanghai) Limited

Honey Sterilizer Machinery,Concentrated Juice Sterilization Machine,Automatic Tube Filling Machine

Jump Machinery (Shanghai) Limited

Honey Sterilizer Machinery,Concentrated Juice Sterilization Machine,Automatic Tube Filling Machine

| Unit Price: | USD 45500 - 46000 / Set/Sets |

|---|---|

| Payment Type: | L/C,T/T,MoneyGram |

| Incoterm: | FOB,CFR,CIF,EXW |

| Min. Order: | 1 Set/Sets |

Applicable Industries: Manufacturing Plant, Food & Beverage Factory

Marketing Type: New Product 2020

Warranty Of Core Components: 1 Year

Core Components: Plc

Condition: New

Place Of Origin: China

Key Selling Points: High Productivity

Video Factory Inspection: Provided

Mechanical Test Report: Provided

Core Component Warranty Period: 1 Year

Old And New: New

Warranty Period: 1 Year

Core Selling Point: Easy To Operate

Weight: 2000 KG

Packaging: Standard export package.If customer have specail requirement,we will do as customer require

Transportation: Ocean,Land,Air

Supply Ability: 100 Set/Sets per Month

Port: Shanghai Port

Payment Type: L/C,T/T,MoneyGram

Incoterm: FOB,CFR,CIF,EXW

For Turnkey Food Beverage Production Line/Can Food Machinery/ Fruits Juice Machinery/Tomato Sauce Machinery/Fruits Jam Machinery/Milk Yogurt Machinery Please Contact us. Tubular Sterilizer is mainly used for the sterilization and cooling of various concentrated fruit purees and various sauces. The touch screen operation is fully automatic control and has a self-cleaning and reverse cleaning system. Widely used in the determination and update of the original formula of milk, juice, tea beverages, milk-containing beverages, ketchup, condiments, beer, cream, ice cream, egg products, solid powders, etc., product taste screening, color evaluation, and stability Agent/emulsifier application, new product development and sample production.

Working principle of 2-tube sterilizer

Tubular sterilizer is an indirect heating sterilization equipment, which is one of the applications of tubular heat exchangers in the food industry. Working principle of tubular sterilizer:

1. Feed the material into the stainless steel heating tube with a high-pressure pump. After the steam enters the shell space, the material flowing in the tube is heated. After the material goes back and forth several times in the tube, it reaches the required temperature and holding time for sterilization and then is discharged as a product. If it fails to meet the requirements, the recirculation pipe will return to the sterilization operation.

Second, the process flow of the tubular sterilizer:

5°C feed--65°C homogenization—85/137°C sterilization, heat preservation for 5-30 seconds---5-90°C discharge---buffer tank/filling machine (the sterilization machine process is designed according to user requirements)

5°C feed--65°C homogenization—95°C sterilization, heat preservation for 30 seconds--137C sterilization, heat preservation for 5 seconds---25°C discharge---sterile tank/sterile filling machine (sterilization machine process) Designed according to user needs)

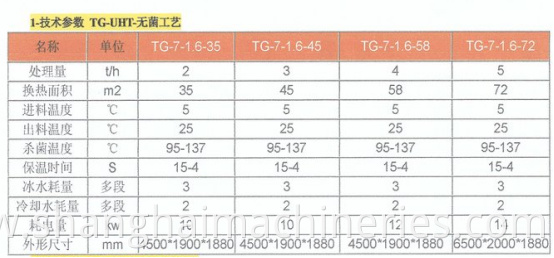

According to the 7T/H tube-type aseptic UHT sterilization machine and the aseptic cold filling process as an example, the energy consumption of the equipment is as follows:

1 Steam consumption: 560kg/h (0.8Mpa)

2 Compressed air: the maximum consumption is ≥0.3 cubic meters per minute, and the pressure is 0.7Mpa. 3 Soft water: the maximum consumption is ≥12T/h, and the pressure is 0.3Mpa.

3 Soft water: the maximum consumption is ≥12T/h, and the pressure is 0.3Mpa.

4 Cooling water consumption: 21000kg/h, pressure 0.25Mpa. 5 Consumption of ice water: 21000kg/h, pressure 0.25Mpa.

Application scope of 3-tube sterilizer

Tubular sterilizers can mainly produce fruit juice, milk, ice cream, jam and other products aseptically, so that the products can maintain their quality and freshness for a long time.

Features of 4-tube sterilizer

1 It can adapt to a wide range of viscosity, and it can also be used for the sterilization of fibers and particles;

2 Instant processing is used to maintain the original flavor of the product;

3 It adopts fully automatic or semi-automatic control mode, which is convenient for users to use;

4. The product can be uniformly heat treated, and at the same time, the heat recovery rate can reach 85%;

5. When the product is in the equipment, it will start the automatic cleaning function, so that the product does not stick to the tube; 6. Equipped with a PID temperature control system, which can monitor the temperature in real time;

7. Installation and disassembly are relatively easy, which is convenient for later maintenance and repair.

Product Categories : Pet Food Processing Line > Cat Food Production Line